Get Quote

News

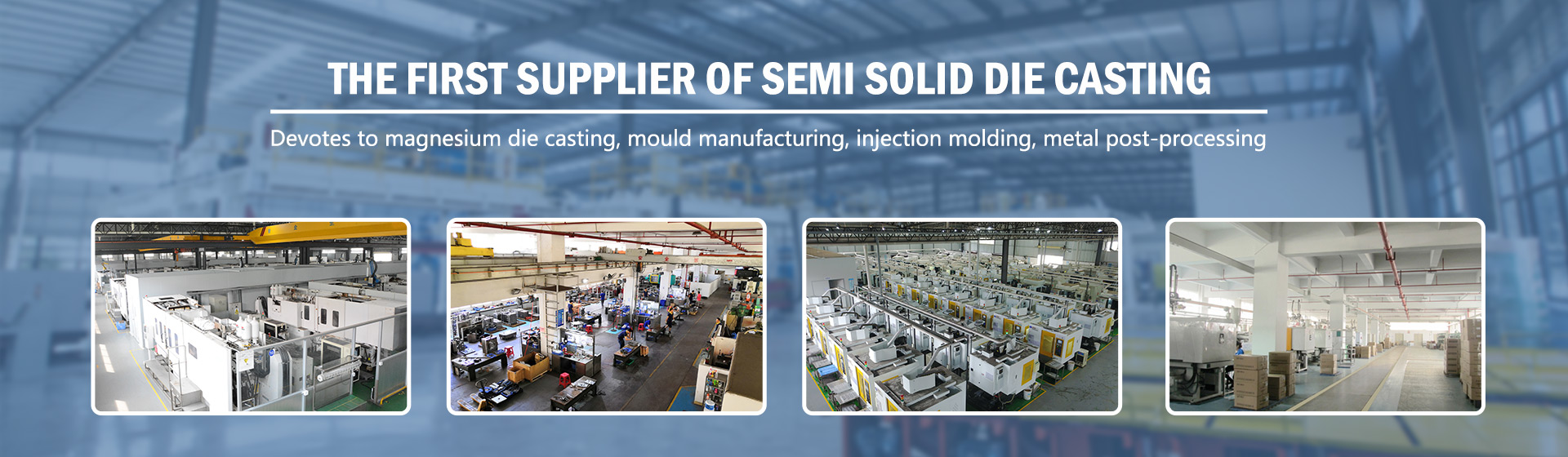

- Lightweight product - stabilizer, the representative of China's famous stabilizer brand communicates with our companyChina's well-known brand of hand-held stabilizers arrived at Ruizhun for factory visits and follow-up cooperation negotiations The exhibition hall, semi-solid die casting zone, CNC processing zone, and metal post-processing zone were visited. Ruizhun is in line with the market lightweight trend, semi-solid magnesium alloy dies casting process has matured. In 3C electronics industry and automobile industry, lightweight has been implemented. With the upgrading of products and the application of new technologies and new energy sources, products are developing towards high intelligence. High precision, high intensity, and lightweight are the inevitable directions. They have been partially implemented in the 3C electronics and automotive industries. The concept of pursuing environmental protection, health, and sensory enjoyment is imperative. The application of new materials is imperative. Ruizhun Company is an enterprise which helps to lighten the market and devotes itself to the development and application of semi-solid light magnesium alloys in batch production, precision injection molding, CNC processing and mold manufacturing. Semi-solid die casting is a one-stop enterprise with better compactness and more stable product size than traditional die casting. It has many years of production and development experience, thanks to our strong professional and technical team and the first one. The imported semi-solid magnesium alloy die casting production equipment (the factory covers an area of 70,000, equipped with 100 rheological semi-solid magnesium alloy die casting machines, 180 Franc*CNC processing centers (processing specifications: 400 mm *300 mm *500 mm, diameter < 300 mm processing accuracy: +0.02 mm). Ten groups of die manufacturing teams and matching die-making equipment in factory B are dedicated to die casting service; the company has passed ISO 9001:2015, ISO 14001:2015. ISO/TSTS16949:2016 Quality Management System Certification and North American UL Safety Certification;

2019 03/02

- Motorcycle Manufacturing Enterprises Visit Semi-solid Die Casting Workshop of Magnesium Alloy CompanyOn December 25, 2018, a well-known motorcycle manufacturer entrusted Johnson Chang, RZJM office in Hong Kong, to visit the company's headquarters. Accompanied by Mr. Hong, the chairman of the company, to visit and explain the customer's related problems in real time. The customer is a motorcycle manufacturer, so we mainly visit the semi-solid die casting workshop of magnesium alloy. There are 100 integrated rheological semi-solid die casting machines for magnesium alloys. Twenty traditional liquid die casting machines are equipped with automatic feeding and clamping system. Provide the largest and most advanced magnesium alloy forming service for magnesium alloy die casting business CNC Fine Processing of Supporting Equipment of Die Casting Products Company,Equipped with 180 Franc CNC Machining Centers, Precision Processing Die Casting Products Stamping equipment In order to enhance the performance of metal products and meet the special appearance requirements of products, post-processing workshops have been set up in the company, and three new automatic spraying production lines have been built in 2018. Compared with the original way, magnesium alloy products are more delicate and uniform after-treatment, higher processing standards, and more perfect for automotive appearance accessories and 3C electronic products.

2018 12/25

- dedicated to semi-solid die casting, light alloy die casting, precision injection molding, die manufacturing The preparatory work for B plant expansion project has been completed.A sweeping robot, also known as the automatic sweeper, intelligent vacuum cleaner, robot vacuum cleaner, is a kind of intelligent household appliances. It can automatically clean the floor in the room with certain artificial intelligence. Generally, brushing and vacuum are used to absorb ground debris into their own garbage collection boxes, thus completing the function of ground cleaning. In general, robots that finish cleaning, vacuuming and wiping are also classified as sweeping robots. TPE material and Thermoplastic Elastomer are thermoplastic elastomer materials used in manufacturing electronic products. They have the characteristics of high strength, high resilience and injection processing. They are widely used, environmentally friendly, non-toxic and safe, and have excellent coloring properties. Soft touch, weathering resistance, fatigue resistance and temperature resistance, excellent processing performance, no vulcanization, can be recycled to reduce costs. It can be used for secondary injection molding, coating and bonding with PP, PE, PC, PS, ABS and other matrix materials, but also can be formed separately. Preparations for the expansion project of Ruizhun B plant, which is dedicated to the research and development of semi-solid magnesium alloy die casting, light alloy dies to cast, precision injection molding and die manufacturing, have been completed. After cooperating with China's domestic smart electronics manufacturers, the supply continues to grow, leading to our original B factory warehouse can not meet the current production needs, so our expansion project preparation has been completed ready for expansion.

2018 10/20

- Precision injection molding machine dynamicsBeijing time September 30th,Dongguan City Ruizhun Precision Metal Co., Ltd second new purchase two-color injection molding machine. Ruizhun Precision Metals Co., Ltd. has seen a dramatic increase in business volume since its launch on the international website, especially in mold manufacturing, magnesium alloy die casting and precision injection molding. In order to relieve production pressure in the B plant area and enhance the overall production capacity of the enterprise, it was approved to purchase a 300T dual-color injection molding machine for special product production services. It is estimated that it will last 1400PCS/ days. Dongguan City Ruizhun Precision Metal Co., Ltd., mainly engaged in semi-solid die casting (magnesium alloy die casting), light alloy die casting, precision injection molding, mold manufacturing, CNC processing. The establishment of two large factories responsible for different projects, all processes are completed within the plant area. 101 sets of rheological semi-solid die casting machines and 200 sets of CNC processing machines in plant A, 10 mould manufacturing teams in plant B, 45 sets of matching machines for mould manufacturing, 50 sets of single and double color injection moulding machines for each tonnage, with a strong production capacity and R&D team and a product quality management laboratory, are committed to creating JIM supply for long-term customers. Chain "- production priority, production price concessions, investment priority.

2018 09/30

- Purchase trend of precision injection molding plantBeijing time August 20, 2018, Ruizhun Precision Metal Co., Ltd. B factory, focusing on the service of plastic injection molding, mold manufacturing supply chain, after the purchase of new machines to expand injection production, the original reserve material does not meet the daily production, the purchase of Paint-free Aesthetic Plastics ABS materials 20 tons. ABS material: ABS has the common properties of both three components, A makes it chemical corrosion resistance, heat resistance, and a certain degree of surface hardness, B makes its high elasticity and toughness, S makes it have thermoplastic processing molding characteristics and improve electrical properties. Therefore, ABS plastic is a kind of "tough, hard, rigid" material with easy access to raw materials, good comprehensive properties, and wide use. ABS has excellent comprehensive physical and mechanical properties and good low-temperature impact resistance. Dimensional stability. Electrical properties, wear resistance, chemical resistance, dying, finished products processing and mechanical processing are better. Advantages of free spraying plastic Super gloss: super high gloss is achieved by using special raw materials and auxiliaries. Chemical resistant solvents: special chemicals are used to improve the chemical resistance of materials. Green environmental protection: avoid the environmental pollution caused by spraying; materials can be recycled 100%. Cost saving: simple process and high yield. Compared with spraying, the comprehensive cost is reduced by 20-50% The free sprayed plastic can be well molded and molded. For example, the housing of the pull rod box can be made of the metal imitated material by suction molding. Non-spraying plastic is the most widely used processing method in injection molding. In order to achieve the best appearance of the product, high-gloss injection molding technology is often used to achieve the appearance requirements of no weld lines. Our company specializes in light alloy die casting, semi-solid die casting, mold manufacturing, precision injection molding, CNC processing supply chain services. Plastic injection molding service can choose materials according to the customer's product needs, or our company's R&D team can give the best material suggestions to customers. WE ARE--RZJM

2018 08/20

- Application of Magnesium Die CastingMagnesium alloy has the good lightweight, cutting property, corrosion resistance, shock absorption, dimensional stability and impact resistance. It is far superior to other materials. These features make magnesium alloys used in a wide range of fields, such as transportation, electronics, medical, military, and so on. This trend is only increasing. Especially in the fields of 3C products (computer Computer, consumer electronics Consumer Electronic Product, communication Communication), high speed iron, automobile, bicycle, aeronautics and space, architectural decoration, hand-held tools, medical and rehabilitation equipment and other fields, it has great potential and has become the development direction of new materials in the future. Its processing and corrosion and mechanical properties have many characteristics: fast heat dissipation, light quality, good rigidity, certain corrosion resistance and dimensional stability, impact resistance, wear resistance, good attenuation performance and easy recovery; in addition, it has high thermal and conductive properties, no magnetic, good shielding and non-toxic characteristics. Application: magnesium alloys are widely used in portable equipment and the automotive industry to achieve lightweight purposes. Under the same strength parts, magnesium alloy parts can be made thinner and lighter than plastics. In addition, because the specific strength of magnesium alloy is higher than that of aluminum alloy and iron, it can reduce the weight of aluminum or iron parts without reducing the strength of parts. Electronic communication: Due to the development of digital technology in the electronic information industry, the market is becoming more and more highly integrated, thin, miniaturized and environmentally friendly to electronic and communication products. Engineering pigment has been used as the main material, but its strength can not be compared with that of metal. Magnesium alloys have excellent Thin-walled Casting properties. The wall thickness of the castings can reach 0.6~1.0mm, and the strength, stiffness and anti-collision ability are maintained. This is very beneficial to the requirements of ultra-thin, ultra light and miniaturized products. This is incomparable to the engineering pigments. Magnesium alloy components of an unmanned aerial vehicle. Automobile industry: There are two ways to lighten the automobile: first, to optimize the structure; the two is to choose lightweight materials. Aluminum alloy, plastic (resin matrix composite) and magnesium alloy are three kinds of materials which are considered to be ideal at present. Magnesium alloy dies casting is the lightest of all the die casting alloys. It is a very competitive lightweight material for an automobile. A large number of magnesium alloy parts are produced to replace plastic, aluminum, and even steel parts. With the development of technology, magnesium alloys will be more widely applied in the automotive field. Magnesium Die Casting Laptop: The use of magnesium alloy as the shell of a notebook computer is almost based on all the advantages of magnesium alloy. The shock resistance improves the reliable operation of the computer components; the anti-electromagnetic interference and electromagnetic shielding performance ensure the information security of the computer; the excellent thermal conductivity greatly improves the heat dissipation of the electroencephalon. Precision Mg Die Casting,

2018 08/09

- Emption New Type of Injection Moulding Machine of Injection Molding SuppliersOn July 11, 2018, Beijing time, two new type of new dual color injection machines [Haitian Mars II Series Injection Moulding Machine" and [BN-200-2C" were purchased and assembled, and they were formally put into production after the trial production samples were confirmed. The highly optimized servo-hydraulic technology improves efficiency and reduces energy consumption. The optimized clamping unit provides lower energy consumption and faster movement to reduce the cycle time. A fixed pressure plate with concentrated force loading and less pressure plate deflection. The redesigned mobile platform provides centralized force distribution from the toggle system to the mold. Results: high stiffness and stability Ruizhun Precision Metal Co., Ltd specializes in semi-solid die casting, traditional die casting, mold manufacturing, injection moulding and other processing services. It produces light, high quality, high efficiency, energy saving, environmental protection die casting and injection products. The A factory is located in Qiaotou town, Dongguan. Ruizhun Precision Metal Corporation covers an area of 70000 square meters. It has 800 production workers and 150 managers, and imports 101 semi-solid die casting magnesium alloy casting machines. High precision injection molding machine 90, is China's largest semi-solid die casting magnesium alloy enterprises, and provide an efficient and advanced die casting processing service of magnesium alloy. B factory is located in the town of Fenggang, Dongguan. Best Mold Co., Ltd. covers an area of 10000 square meters. Has 30 injection molding machines, 10 mold manufacturing working group, 15 years experience in injection molding. It is focused on plastic molding and mold manufacturing.

2018 07/12

- Semi Solid Die Casting on RZSemi-solid die casting is called SSC for short, which is the new metal forming technology in the world. The magnesium/aluminum light alloy material is heated to semisolid to be molded in high speed and high-pressure metal mold so that the product has high density, high strength/stiffness, high precision, fine surface, corrosion resistance, no pollution... Characteristics. 1.processing specifications: The projection area is less than 800cm2, the thickness is more than 0.3mm, and the weight is less than 800g. 2.Temperature / density: It is lower than the traditional die casting temperature 60~100 C, avoiding melting damage. 0.4 to 1.8, the porosity of conventional die casting is 2.5 ~ 3, quality improvement and mechanical properties. Can improve; 3.force / energy saving / environmental index: Shrinkage reduces alloy to withstand higher pressure; semi-solid slurry has no macro bias. The analysis shows that the casting alloy has uniform properties, short forming time, small mould consumption, and no contact with space. Gas, no pollution. Magnesium alloy materials: AZ91D and AM60B AZ91D has good corrosion resistance and casting properties for automobile, computer parts, sports equipment, hand tools and so on. AM60B has high ductility and impact resistance for vehicle interior assembly, steering wheel, chair frame and instrument panel rack. Better research and development of rare earth magnesium alloys. Applicability: only semi-solid alloy can meet the automobile brake cylinder. The wheel hub, steering knuckle, steering gear, pump body, valve body, and suspension bracket have high density, high strength, and high reliability. Widely used in aviation, automobile, communications, electronic and electrical appliances, equipment, medical and other high application industries, or "high quality, efficient, energy saving, environmental protection" industry. Semi-solid casting is composed of rheocasting and thixotropic casting. We use the rheology casting process with short process, high efficiency and the most advanced. Our company has a design and development team of about 150 people to design molds, ten mold manufacturing groups manufacturing molds, two large factories specializing in the production of injection and die-casting products. The company has 101 units of magnesium alloy integrated semi-solid die-casting machine, specializing in magnesium alloy die-casting, currently the largest and high standard in the world. The inspection instrument and equipment for injection molding production, customer confirmation, the eight processes are completed in the factory, each process has a special person to follow up, and can keep communication with the customer on the product problem at any time. Customers confirm samples and produce them in bulk and export to customer companies.

2018 06/08

- Semi-Solid Die Casting, Injection Moulding and Mold Manufacturing Supplier Official International Website Officially LaunchedBeijing time, on June 7, 2018, the international official website of Ruizhun Precision Metal Co., Ltd (RZ) . was officially launched to meet the needs of the world die casting industry, the mold industry, and the injection industry. Ruizhun Precision Metal Co., Ltd (RZ) is China's national high-tech enterprises and key enterprises in Guangdong, with registered capital 120 million, have been developed into Chinese high-tech enterprises and have applied for 18 patent technologies and have the right to import and export, specializes in Semisolid Die Casting, traditional die casting, mold manufacturing, injection molding and other processing services. It produces light, high quality, high efficiency, energy saving, environmental protection die casting and injection products. The company has two subsidiary companies: a factory is an RZ Own factory area, specializing in the production of semi-solid die casting products; B factory is Bai run mould Co., Ltd., engaged in injection production, mold manufacturing. The A factory is located in Qiaotou town, Dongguan. Ruizhun Precision Metal Co., Ltd.covers an area of 70000 square meters. It has 800 production workers and 150 managers, and imports 101 semi-solid die casting magnesium alloy casting machines. High precision injection molding machine 90, is China's largest semisolid die casting magnesium alloy enterprises, and provide efficient and advanced die casting processing service of magnesium alloy. B factory is located in the town of Fenggang, Dongguan. Best Mold Co., Ltd. (GR)covers an area of 10000 square meters. Has 30 injection molding Plastic Injection Plastic Molding machines, 10 Mold manufacturing working group, 15 years experience in injection molding. It is focused on plastic molding and mold manufacturing. Ruizhun Precision Metal Co., Ltd. focuses on technology research and development and has a strong R & D team. It has applied for 18 advanced technology patents, turning customers' ideas into products. At the same time, through the BSI certified ISO9001:2008, ISO14001:2004, TS16949 quality management system, the company has a mature product testing laboratory, which can test the quality and details of the die-casting and injection products to ensure the quality of the products according to the needs of the customers. UCT quality. Ruizhun Precision Metal Co., Ltd has many years of casting experience, mold manufacturing, and injection molding, each process has a special person to follow up, and can communicate with customers at any time about the product. Our company has about 100 people in the design and development team to design the mold, two factories have twenty mold manufacturing groups, manufacturing molds, two large factories specializing in the production of injection products, and international inspection standards PROD professional laboratory. The finished product is confirmed with the customer, the eight processes are completed in the factory area after the customer confirms the sample, the batch production, and export to the customer company.

2018 06/07

Email to this supplier